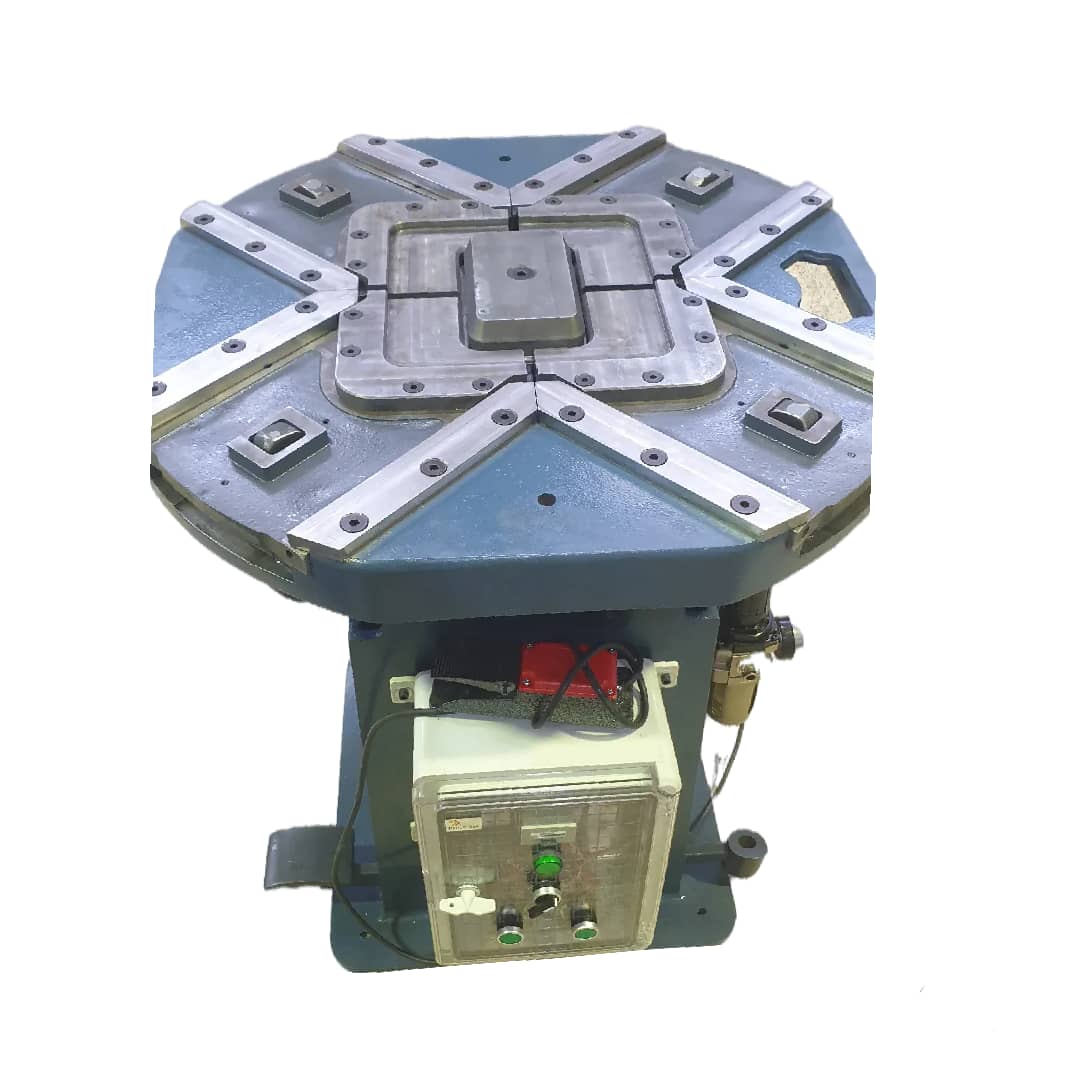

The use of this device is to return the edge of the fuzzy can body, which is done after the operation of squaring the can, in such a way that the edges are placed between the two parts of the mold and with the pressure applied to the surface of the sheet to the extent defined on the mold. It is bent in the same way until it is ready to be closed and finally pressed.

The molds of the rectangular can flanging machine are designed in different dimensions and sizes according to the dimensions of the can and the thickness of the sheet and are installed on the machine.

Phenemar Machinery has tried to design two models of this machine to facilitate this: 1) Pneumatic square can body flanging device

2) Mechanical square box body flanging device

The mechanical flanging device is made from a set of braked gearbox motor, which completes a complete course with each pedal drive and the edge of the can returns uniformly. The speed of this device is about 6% higher compared to the pneumatic device, and it is suggested to most of the metal can manufacturers to use a pneumatic flanger device with a 6 bar atmospheric pressure air compressor if possible.

One of the salient points of the pneumatic flanger is the removal of the engine, gearbox, brake, crank and connecting rod and its settings.

The ability to produce both models in an 8-hour work shift in the amount of 6000 cans

The ability to change the mold (fabric and gonia) for 10 minutes in both models