- The machine has the ability to press metal cans of any size by changing the mold by the operator.

- The production capacity or can press in this machine for 3 seconds, which is about 5,500 to 6,000 pieces of Aleppo in an 8-hour work shift.

- The device has a pneumatic set to facilitate the operator in the pedal set of the device, which includes (pneumatic jack, pneumatic pedal, care unit, electric valve, etc.).

- The device is equipped with an adapter to connect to the conveyor.

- The set of electrical panels of the device is one of the original electrical appliances and is equipped with a Aleppo counter.

- The required air pressure for the care unit and finally the movement of the pneumatic jack is about 3 bar atmosphere, which is possible with the minimum possible compressor.

- It takes about ten minutes for the operator to change the mold, which is easily done with the presence of experts and training to the operator.

- The motor used in the machine is from reputable brands such as Electrogen and Motogen with a specification of 900 rpm and a power of 2.2 kW.

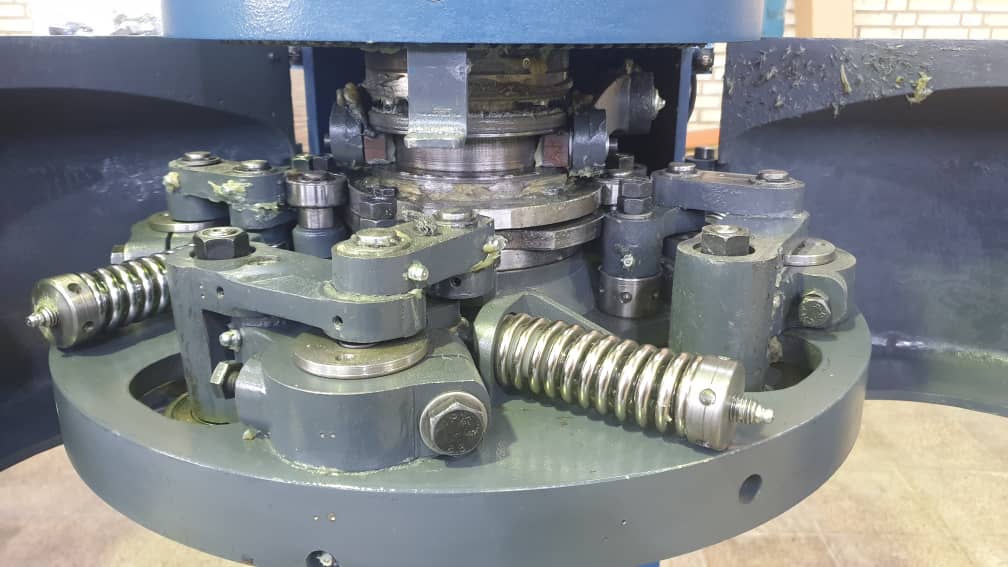

Rectangular can seamer